🌊 Can we employ the integration of rule-based cause and effect AI along with sensors for predictive analytics on rotary devices? 📉

Explore the innovative integration of rule-based cause and effect AI with sensor technology for predictive analytics in rotary devices. This article delves into how this cutting-edge approach can optimize maintenance, improve efficiency, and prevent failures in industrial applications.

🔎 Predictive Analytics and Rotary Devices:

Predictive analytics enables the identification of potential failures or performance issues before they occur. This facilitates proactive maintenance and optimization [1].

🔎 Rule-Based Cause and Effect AI:

AI algorithms can detect patterns and anomalies, indicating potential issues or opportunities for improvement [1]. Rule-based cause and effect AI systems utilize predefined rules and logic to analyze sensor data, identifying potential causes and effects of issues in rotary devices [4].

🔎 Sensors for Leading Indicators:

Leading indicators are measurements or parameters that provide early indications of potential issues or failures in rotary devices [4].

▶️ The collected real-time data from these sensors can be analyzed using predictive analytics algorithms to identify patterns and predict future failures [4].

🔎Wireless Sensor Network Protocol:

The choice of the wireless sensor network protocol depends on factors such as data rate, range, power consumption, and network topology. Commonly used protocols include Zigbee, Bluetooth Low Energy (BLE), and Wi-Fi[2].

▶️ Wireless sensor networks (WSNs) enable the collection and transmission of sensor data from rotary devices to a central monitoring system [5].

▶️ Employing the correct WSN protocol is crucial for ensuring reliable and efficient data transmission, minimizing latency, and optimizing power consumption [5].

▶️ Common WSN protocols used in industrial applications include Zigbee, Bluetooth Low Energy (BLE), and WirelessHART [5].

🔎Benefits of Integration:

▶️ Improved maintenance efficiency and reduced downtime by identifying and addressing potential issues before they lead to failures [6].

▶️ Optimized maintenance schedules and resource allocation based on predictive insights [6].

▶️ Enhanced operational performance and productivity of rotary devices through proactive maintenance and optimization [6].

References:

[1] Sensors | Predictive Maintenance and Intelligent Sensors in Smart Factory: Review

[2] Electronics | Optimization of Routing-Based Clustering Approaches in Wireless Sensor Network: Review and Open Research Issues

[3] AI-big data analytics for building automation and management systems: a survey, actual challenges and future perspectives | Artificial Intelligence Review

[4] Sensors | Predictive Maintenance and Intelligent Sensors in Smart Factory: Review

[5] Electronics | Optimization of Routing-Based Clustering Approaches in Wireless Sensor Network: Review and Open Research Issues

[6] AI-big data analytics for building automation and management systems: a survey, actual challenges and future perspectives | Artificial Intelligence Review

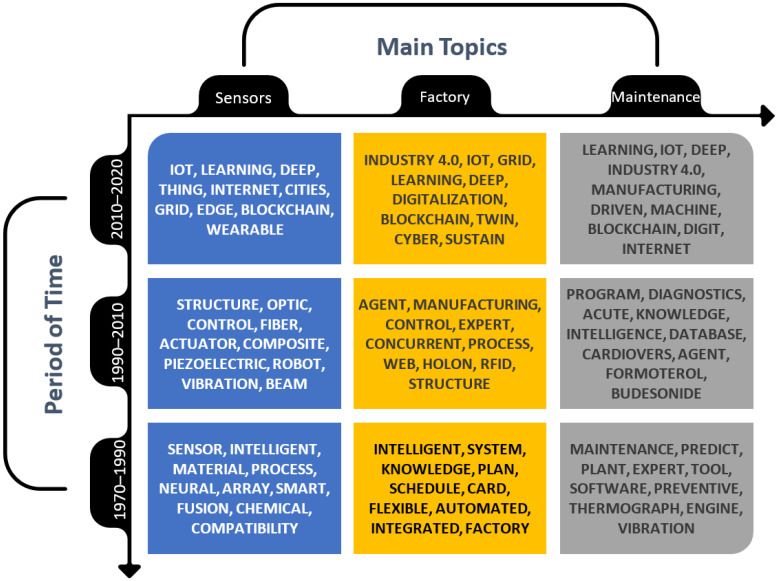

The research by Martin Pech et al. discusses the core technologies of Industry 4.0, including IoT, cloud computing, and high-volume data analysis. It explains that IoT involves the integration of sensors and computer technology for wireless communication, while cloud services provide access to shared computing resources. These technologies enable the concept of a smart factory, but the large amounts of data collected require high-volume data analysis tools such as data mining or machine learning.

This research also discusses smart sensors, which are wireless IoT devices that use the internet and the cloud. These sensors have low power consumption, automatic diagnostics, and the ability to process and share data in real-time. The importance of robustness, including durable materials and situational protection, is emphasized.

The three types of sensors mainly used for predictive maintenance in smart factories are intelligent sensors, IoT devices, and cloud-related technologies. Vibration analysis, SCADA systems, CNC machine sensors, and PLCs are commonly used for collecting and monitoring machine data. The challenges in this field include big data analytics, interoperability of sensors and maintenance systems, decentralization of maintenance control, and the availability and reconfigurability of sensors.

The proposed Smart and Intelligent Predictive Maintenance (SIPM) system consists of four major subsystems: production, monitoring, planning, and maintenance. These subsystems communicate through IoT and cloud-based technologies, allowing real-time management and planning to reduce production downtime.

From a managerial perspective, the predictive maintenance system in smart factories provides early warnings, especially in high-risk industries. It helps detect weak signals with strategic impact and can lead to reduced hierarchical levels, increased employee autonomy, and effective implementation of innovation processes. Managers face the challenge of selecting intelligent sensors based on criteria such as sensitivity, cost, flexibility, and size.

Future research directions include advanced machine learning methods like deep learning and data-driven algorithms. The concept of "Machine as a Service" (MaaS) is considered a suitable trend for future research. Additionally, evaluating building performance models at a reasonable cost is an interesting area of research.

Overall, the research highlights the importance of IoT, cloud computing, and data analysis in Industry 4.0, discusses smart sensors and their applications in predictive maintenance, presents the SIPM system for smart factories, and addresses managerial considerations and future research directions.

Ref: Pech, M., Vrchota, J., & Bednář, J. (2021). Predictive maintenance and intelligent sensors in smart factory. Sensors, 21(4), 1470.

Wireless Automation for Reliability

Jonas BergeAuthor, award-winning speaker, digital transformation advisor, researcher, and consultant. Called thought leader and innovative problem solver115 articles FollowingJuly 30, 2023Open Immersive Reader

- Plant operations are challenged with equipment failure, keeping up with preventive maintenance, and inspection rounds

- Work in plant is transforming by expanding and automating data collection and interpretation

- The recommendation is for the I&C team to deploy software and sensors, but these must have some important characteristics

- The result is greater availability and autonomous operation

Reliability managers, maintenance managers, integrity managers, and their teams of engineers, supervisors, and technicians work to keep the plant up and running 24/7. We need to give them great tools to be successful. Industrial Internet of Things (IIoT), digital transformation (DX), predictive maintenance (PdM), condition-based maintenance (CBM), and prescriptive maintenance (RxM) are heralded as key solutions and methodologies, and they are, and all of them are about automation. Ever since 2015 I call the 24th of July (24/7) the World Reliability Day to recognize the women and men who keep things running 24 hours a day, 7 days a week (24/7) so I’d like to share some ideas on how to make reliability and maintenance management in plants easier by providing personnel with new automation tools. Let’s examine how the work of reliability and maintenance engineers is changing with wireless sensors. And it doesn’t have to be difficult. It can be done by reliability and maintenance engineers working with your I&C team. What are the recommended practices for the I&C team to build and support these solutions to provide real-time prediction and indication of equipment health? Here are my personal thoughts:

The most important fact that many have missed in the past is that the wireless sensor network (WSN) technology you choose makes a huge difference in the long-term viability of these condition monitoring solutions. With the wrong WSN you cannot pull current information from sensors on demand when you need it, and you cannot easily integrate the sensor measurement data into analytics and other third-party platforms and apps without costly coding and scripting.

Plant Challenges

Reliability, maintenance, and integrity challenges in a plant include equipment failure which leads to unscheduled downtime, lost revenue, corrective maintenance cost (repair), production downtime penalty, and demurrage. Preventive maintenance has associated scheduled downtime (some of it unnecessary) and preventive maintenance cost (some of it unnecessary). Inspection rounds is another function with associated inspection cost (transport, outsourced services) and productivity numbers. Lastly loss of containment which leads to cleanup cost and fines. And it only gets more difficult as the plant gets older. Many of these stems from manual practices like manual data collection walking the plant and manual data interpretation. These are the reasons why plants want to change how reliability, maintenance, and integrity is managed.

Work Transformation

The new ways of working, of managing reliability, maintenance, and integrity include automatic data collection, automatic data interpretation, and automatic workflow. That is, predictive maintenance, condition-based maintenance, and prescriptive maintenance. This is useful in any plant, but particularly helpful for normally not manned sites like offshore platforms and remote wellheads looking for autonomous and centralized operations. This is the vision of how plants want to change how reliability, maintenance, and integrity is managed. Now, just like you can’t drive your car looking at the maintenance log, you must look at the real-time indicators on the dashboard, you cannot run a plant looking at the maintenance log either, you need to provide real-time indicators.

The New Automation Solutions

To achieve this vision, plants deploy Industrial Internet of Things (IIoT) and digital transformation solutions which is just another name for automation solutions. Most of these solutions are a combination of ready-made analytics software for the automatic data interpretation and underlying sensors for the automatic data collection. This is a second layer of automation, beyond the P&ID, what some refer to as hyper-automation. Engineering is where the vision statements of holistic transformation come down to implementation to address individual use-cases. Popular examples of condition monitoring solutions include packages for pumps, cooling towers (CT), air-cooled heat exchangers (ACHX), pipes (corrosion and erosion), control valves, heat trace, pressure/vacuum relief valves (PVRV), dampers, filters, and strainers, and automating inspection rounds. The recommendation is to start with these use-cases, but there are more.

Pump Monitoring Solutions

Pump failure modes include cavitation, strainer plugging, motor winding insulation breakdown, bearing wear, and mechanical seal leaks. These failure modes and their cause & effect, the symptoms, which are leading indicators of impending failure are well understood.

Software

Software, an analytics app, based on Artificial Intelligence (AI) is used to automatically predict cavitation, strainer plugging, motor winding insulation breakdown, bearing wear, and mechanical seal leaks in the pumps. The recommendation is to use a specialized pump app with special features for pump analytics.

This is analysis and prediction that in the past required a human with expert know-how. By automating the analysis, it gets done continuously, not just once a month. This was not possible with a manual process. With these automatic tools, personnel can manage many more pieces of equipment than what was analyzed manually in the past. Experts can focus on the pieces of equipment requiring attention, without wasting time on those that don’t.

The recommendation is to use readymade apps using rule-based AI embedding the well-known cause & effect relations to predict using real-time sensor data. With this approach years of historical data, data cleansing, algorithm training, modelling, and testing is not required. The predictions are deterministic, not probabilistic. The reliability and maintenance engineers are responsible for the availability of the equipment and therefore need this information in software on their laptop at their desk, so this information shall be displayed in apps for them, not in the DCS operator console in the control room, because that is not where they work. It’s the same app framework for the various kinds of equipment in the plant.

Sensors

The recommendation is to add pressure, vibration, differential pressure, temperature, and hydrocarbon/chemical leak sensors to take the place of manual rounds to automatically collect the data required by the analytics for robust and timely prediction. The exact configuration of sensors depends on the failure modes you want to predict. Reliability, maintenance, and integrity engineers work together with the I&C engineers to determine which sensors are required on each piece of equipment.

This is data collection and input that in the past required a human to go out with portable testers or reading mechanical gauges. By automating the data collection, it gets done once a day, once an hour, once a minute or every few seconds - not just once a month. This was not possible with a manual process. Sensors are installed on equipment in every corner of the plant. With these sensors, personnel can “inspect” many more pieces of equipment than what was covered manually in the past.

The recommendation is to add wireless and non-intrusive sensors as they require no power cord, no signal wires, and no I/O cards. And there is no cutting, drilling, or welding required for installation of many of these sensors. That is, many of these sensors can be installed while production is running.

Cooling Tower Monitoring Solutions

Cooling tower failure modes include motor winding insulation breakdown (fan and pump), bearing wear (motors, gearbox, fan, and pump), strainer plugging, pipe corrosion, fill fouling, as well as water chemistry issues. These failure modes and their cause & effect, the symptoms, which are leading indicators of impending failure are well understood.

Software, an analytics app, based on AI is used to automatically predict motor winding insulation breakdown, bearing wear, strainer plugging, pipe corrosion, fill fouling, as well as water chemistry issues in the cooling towers. The exact configuration of sensors depends on the failure modes you want to predict. The recommendation is to use a specialized cooling tower app with special features for cooling tower analytics.

The transformative nature of the software is the same as described for pumps above. The general software attributes required are also the same as for pumps.

The recommendation is to add pressure, vibration, differential pressure, multi-temperature, level, flow, pH, conductivity, and relative humidity sensors to take the place of manual rounds to automatically collect the data required by the analytics for robust and timely prediction.

The impact the sensors have is the same as described for pumps above. The required sensor attributes are also the same as for pumps.

Air-Cooled Heat Exchanger Monitoring Solutions

Air-cooled heat exchanger (ACHX) failure modes include fan motor winding insulation breakdown, bearing wear, louver defect, pitch actuator failure, and fin fouling. These failure modes and their cause & effect, the symptoms, which are leading indicators of impending failure are well understood.

Software, an analytics app, based on AI is used to automatically predict fan motor winding insulation breakdown, bearing wear, louver defect, pitch actuator failure, and fin fouling in the air-cooled heat exchangers. The exact configuration of sensors depends on the failure modes you want to predict. The recommendation is to use a specialized ACHX app with special features for ACHX analytics.

The transformative nature of the software and the general software attributes required are the same as described for pumps above.

The recommendation is to add pressure, vibration, multi-temperature, and position sensors to take the place of manual rounds to automatically collect the data required by the analytics for robust and timely prediction.

The impact the sensors have, and the required sensor attributes are the same as described for pumps above.

Pipe and Vessel (Corrosion and Erosion) Monitoring Solutions

Pipe and vessel failure means rupture due to wall thinning because of corrosion and erosion. The cause & effect, the symptom, which is a leading indicator of impending failure is well understood.

Software, an analytics app, based on AI is used to automatically predict rupture due to wall thinning because of corrosion and erosion in the pipe and vessels. The recommendation is to use a specialized corrosion/erosion app with special features for corrosion/erosion analytics.

The transformative nature of the software and the general software attributes required are the same as described for pumps above.

The recommendation is to add Ultrasonic Thickness (UT) sensors to take the place of manual rounds to automatically collect the data required by the analytics for robust and timely prediction.

The impact the sensors have, and the required sensor attributes are the same as described for pumps above.

Control Valve Monitoring Solutions

Control valve failure modes include stuck valve, broken actuator spring, stem damage, stick-slip action, air supply loss, filter regulator failure, actuator pressure imbalance, air leak (fittings, pipe/tube, actuator), deteriorating stem packing, and limit cycle. These failure modes and their cause & effect, the symptoms, which are leading indicators of impending failure are well understood.

Software, an analytics app, based on AI is used to automatically detect stuck valve, broken actuator spring, stem damage, stick-slip action, air supply loss, filter regulator failure, actuator pressure imbalance, air leaks, deteriorating stem packing, and limit cycle in the control valves. The recommendation is to use a specialized control valve app with special features for control valve analytics.

The transformative nature of the software and the general software attributes required are the same as described for pumps above. Soon, control valve analytics will run in the smart valve positioner, and the software at the office desk will be mostly for visualization of the diagnostics from the analytics in the positioner.

The recommendation is to have valve stem position, supply air pressure, actuator air pressures, temperature, and internal pneumatic relay position sensors to take the place of manual rounds to automatically collect the data required by the analytics for robust and timely prediction.

Deployment of the sensors in the case of control valve analytics has a different approach. These sensors are built into the smart valve positioner as a single integrated unit. A valve positioner is not wireless as it uses 4-20 mA signal to get the desired valve position setpoint from the control system and for power. However, if the control system does not support HART communication and HART-IP pass-through, the positioner can be fitted with a wireless adapter. The impact the sensors have is the same as described for pumps above.

Pressure/Vacuum Relief Valve / Breather Valve Monitoring Solutions

Pressure/Vacuum Relief Valves (PVRV) a.k.a. breather valve failure modes include failed pressure-side valve and vacuum-side valve, but failure of associated tank blanketing valves and emergency vent valve failure can also be detected. These failure modes and their cause & effect, the symptoms, are well understood.

The recommendation is to add proximity sensors with a discrete transmitter to automatically collect the data required by the analytics for robust and timely detection.

The impact the sensors have, and the required sensor attributes are the same as described for pumps above.

Heat Trace Monitoring Solutions

Heat trace failure means the piping goes cold with various negative impacts depending on the application. The cause & effect, the symptom, which is a leading indicator of impending failure is well understood.

The recommendation is to add temperature sensors along the heat trace system to automatically collect the data required by the analytics for robust and timely prediction.

The impact the sensors have, and the required sensor attributes are the same as described for pumps above.

Damper Monitoring Solutions

Damper failure modes include stuck and bent linkage. These failure modes and their cause & effect, the symptoms, are well understood.

The recommendation is to add a position sensor to automatically collect the data required for robust and timely detection.

The impact the sensors have, and the required sensor attributes are the same as described for pumps above.

Filter and Strainer Monitoring Solutions

Filter and strainer failure means blocked/plugged. The cause & effect, the symptoms, which is an indicator of impending failure is well understood.

The recommendation is to add a differential pressure sensor to automatically collect the data required for robust and timely prediction.

The impact the sensors have, and the required sensor attributes are the same as described for pumps above.

Inspection Round Solutions

Many other equipment in the plant also relies on manual inspection and testing walking down the plant carrying portable testers and reading mechanical gauges which is very time consuming and error prone. This also includes for instance conveyor belts, agitators, blowers, and many more.

Software, a simple monitoring app, with trend and alarm, is used to automatically detect out-of-limit conditions in equipment.

The transformative nature of the software is the same as described for pumps above. The general software attributes required are also the same as for pumps.

The recommendation is to add pressure, vibration, differential pressure, temperature, multi-temperature, level, and flow sensors to take the place of manual rounds to automatically collect the data required to detect out-of-limit conditions.

The impact the sensors have, and the required sensor attributes are the same as described for pumps above.

Operational Excellence

As a result of improved reliability, maintenance, and integrity practices enabled by these new automation tools, the plant will see improvements in equipment availability which brings reduced unscheduled downtime, greater revenue, reduced corrective maintenance (repair) cost, reduced production downtime penalty, and reduced demurrage. Condition-based maintenance which brings reduced scheduled downtime and reduced preventive maintenance cost. Autonomous operation which brings reduced inspection cost (transport, outsourced services), and greater productivity. Integrity which brings reduced cleanup cost and reduced fines.

But, if this additional automation is not deployed, the plant will remain stuck in its old ways, which might be good, but not great. And for a new plant that does not put in the additional automation sets itself up for a reactive maintenance culture and sub-par reliability and integrity.

Wireless Sensor Network Requirements

Sensors are critical to improving reliability, maintenance, and integrity management because analytics software without sensors is like a brain without senses. In an existing plant, wireless sensors are the only practical way since laying cable to hundreds or thousands of additional sensors in a running plant is impractical. That is, the I&C team in the plant must deploy wireless sensor network infrastructure if it doesn’t already have it.

Analytics software without sensors is like a brain without senses.

Now, there are many wireless sensor network (WSN) technologies being touted for plants to choose from, but most are not suitable for plant use-cases because when they were created, they were optimized for other use-cases such as on your person and in your home, smart city, or agricultural use-cases etc. And in some cases the radio technology is proprietary. All those WSN technologies therefore lack features that are critical to large-scale operations in process plants with hundreds or thousands of sensors, solving dozens of use-cases, using sensors for dozens of different kinds of measurements. These critical attributes include automatic conversion of sensor measurement data to OPC and Modbus, central sensor configuration, and common sensor diagnostics management.

Be conscious to not inadvertently direct all your attention solely to one sensor, solving one use-case at hand, forgetting about capabilities of the WSN, because you might end up with the wrong WSN not suitable for many of the other sensor use-cases around the plant you will have to tackle in the future.

Multi-vendor interoperability

Reliability, maintenance, and integrity use-cases around the plant require sensors for vibration, pressure, differential pressure (including level and flow), temperature, ultrasonic thickness (corrosion and erosion), and wireless adapter (on smart valve positioners). Other use-cases for occupational health, safety, and the environment (HS&E), as well as sustainability, production, and quality also require sensors for acoustic (noise), corrosivity, contact, guided wave radar (level), multi-temperature, pulse (turbine flow), level switch, gas concentration (H2S, CO, and O2). Managing multiple WSN in a plant would be a lot of work. You want a single WSN to support all these sensor types. Therefore, when you select a WSN technology for your plant, make sure you can find local vendors for all these sensor types, not just the type of sensor you require for the project at hand. Keep in mind that wireless sensors need national approvals (e.g. radio spectrum), so although a vendor have a particular type of sensor on their website, you need to make sure it has the approvals for use in your country.

The recommendation is to deploy WSN infrastructure based on the WirelessHART (IEC62591) standard. This standard supports sensors from multiple vendors covering all these sensor types.

Automatic conversion to OPC and Modbus

Many vendors offer a bundled kit of wireless sensor plus an app for a specific use-case. For instance, many vendors offer a vibration sensor with a vibration app. At a first glance this may look as if it solves the problem at hand, but in the larger scheme of a plant, such point solutions are not practical because the sensor data is trapped within the bundled app. To improve how work is done in the plant, sensor measurement data must also connect to third-party software apps like the historian, analytics, visualization, and maybe even the control system. Therefore the sensor measurement data must be made available using standard industrial protocols and software interfaces. For most WSN that would require custom coding/programming to a non-standard API or scripting to parse vendor-specific data formats. A system integrator has the programming/scripting skills to setup the system, but it is time consuming and costly, so it usually does not get done. But the worst part is that plant personnel will not be able to support it long-term. When OS and software is patched and upgraded, APIs will break. When devices are replaced, different data parsing is required. The system integrator needs to be called in to fix the code or script when a sensor is replaced. That is, most WSN technologies do not provide simple data integration even though the radio may be based on a standard, or the protocol may be a standard.

The recommendation is to deploy WSN infrastructure based on the WirelessHART (IEC62591) standard. This technology uses well-defined data formats which enables automatic conversion of sensor measurement data to OPC Classic (OPC-DA), OPC-UA, Modbus/RTU, Modbus/TCP, HART-IP, and also other standard industrial protocols in the wireless gateway. That is, custom coding/programming or scripting is not required. Existing and future systems and software in the plant can easily tap into the sensor measurement data. IP-based protocols like OPC-UA, Modbus/TCP, and HART-IP can run all the way to software in the cloud if required. Sensors can be replaced without calling in a system integrator. The risk associated with software patching and upgrade is greatly reduced.

Central sensor configuration

Most WSN only support transmission (publication) of sensor measurement value and simple status. The sensor cannot receive configuration data over the WSN. That is, changing the sensor configuration (such as type of temperature sensor or engineering unit) requires you to travel to site to change the configuration locally at the sensor, which is inconvenient in any plant, but particularly troublesome for offshore installations and other remote sites).

The recommendation is to deploy WSN infrastructure based on the WirelessHART (IEC62591) standard. This technology supports both reading and writing of data from a remote location making it possible to centrally configure sensors from configuration software or an intelligent device management (IDM) system. Moreover, gateways support the HART-IP protocol which seamlessly carries the data between the gateway and software such that additional integration effort is not required to setup such capability. Sensors from multiple vendors can be configured from the same software. Sensors can therefore be configured without going to site.

Common sensor diagnostics management

Again, most vendors offer a bundled kit of wireless sensor plus an app, and the health of the sensor, its diagnostics, is only displayed in that app. Once again, at a first glance, this may look as if it solves the problem at hand, but in the larger scheme of a plant, such point solutions are not practical because with the wide selection of sensor types required in a plant, the I&C engineers that support the sensor system must open multiple apps, possibly on multiple computers, in different locations, to see the health of all sensors. This would not be practical.

The recommendation is to deploy WSN infrastructure based on the WirelessHART (IEC62591) standard. This technology uses well-defined data formats which enables a single common software to display the health of sensors, and status of their individual measurements, from multiple vendors. No need to wade through multiple apps. Moreover, gateways support the HART-IP protocol which seamlessly carries the data between the gateway and software such that additional integration effort is not required to setup such capability. The health of sensors from multiple vendors can be monitored from the same software.

Action Plan: Transformation by Wireless Automation

Transformation of reliability, maintenance, and integrity management requires automation such as wireless sensors and specialized analytics apps. Therefore the recommendation is for companies to assign larger budget to their I&C departments to enable them to deploy the automation required to transform how work is done.

For existing plants:

- Deploy WirelessHART sensor network if you don’t already have it

- Change mechanical gauges to wireless sensors

- Deploy wireless sensors in manual testing positions

- Fit control valves with smart positioners and wireless adapters

- Deploy analytics software

- Deploy OT data management if you don’t already have it

For engineering specs:

- Wireless sensor network gateway:

- Shall use WirelessHART

- Shall have sensor measurement data conversion to OPC-UA and Modbus/TCP

- Shall support HART-IP pass-through

- Wireless sensors:

- Shall use WirelessHART

- Intelligent Device Management (IDM) software:

- Shall support HART-IP

- Shall support FDI

For new projects:

- Include WirelessHART sensor network

- Specify wireless sensors instead of mechanical gauges

- Specify wireless sensors in place of manual testing positions

- Specify smart positioners for control valves

- Specify control system with HART support in AI and AO cards

- Include analytics software

- Include OT data management

Lead the way. Schedule a meeting for 24/7, the World Reliability Day or today.

Share this essay with your maintenance and reliability managers now.

And remember, always ask vendor for product data sheet to make sure the software is proven, and pay close attention to software screen captures in it to see if it does what is promised without expensive customization. Well, that’s my personal opinion. If you are interested in digital transformation in the process industries click “Follow” by my photo to not miss future updates. Click “Like” if you found this useful to you and to make sure you keep receiving updates in your feed and “Share” it with others if you think it would be useful to them. Save the link in case you need to refer in the future.

Published by

Jonas Berge Author, award-winning speaker, digital transformation advisor, researcher, and consultant. Called thought leader and innovative problem solver, award-winning speaker, digital transformation advisor, researcher, and consultant.